Inventory planning and management is a tricky thing. Get it wrong and you’ll be faced with either an out of stock situation or an abundance of slow-moving inventory. For this piece, we will focus on how to best identify slow-moving inventory.

Slow-moving inventory is generally defined as stocks or products that sit in your storage room or warehouse (and have not moved) for a certain period of time. While the classification of what can be considered slow-moving varies depending on the product or industry, most organizations already consider stocks that have not shipped within 90 days as slow-moving.

The challenge with having slow-moving inventory is that it physically eats up space and ties up capital, which can impede cash flow and thus impact your business. There are several factors that can cause this issue: wrong sales forecasts, a market slowdown, aggressive promotions from competitors or even your procurement team just wanting to save on per unit costs by ordering more volume. Whatever the cause, minimizing slow moving inventory leads to positive cash flow and better ROI.

There are several ways to identify slow-moving inventory. One best practice is to properly classify items to ensure better cost management. There are different analysis methods that one can use to categorize inventory.

- • ABC Analysis classifies items based on their yearly consumption value.

- • FSN Analysis is based on quantity, consumption rate and frequency of use. FSN is actually an acronym with F referring to Fast Moving, S to Slow Moving and N to Non-Moving.

- • SDE Analysis classifies items based on how easy or how fast it is to procure them. S stands for scarce items (rare items, not easily accessible and need a long lead time e.g. more than 6 months), D for difficult (can be ordered with a lead time of less than 6 months) and E for products that are easily available.

Want to find out more? Make sure you contact us for all these trending topics and more.

Another method companies use to determine slow moving inventory is by ranking items based on months-on-hand. Months on hand is usually calculated by looking at current inventory quantity and dividing it by monthly average usage. Higher months on hand means the item is slow-moving.Measuring inventory turn-over is another way to identify slow-moving items. This makes use of what is called Turn-Earn Index or TEI. TEI is calculated by multiplying turnover by gross margin and is good way to determine which slow-moving products are still profitable investments for the organization. A high TEI means that the company is still getting a good margin from the product despite it having a slower turnover.

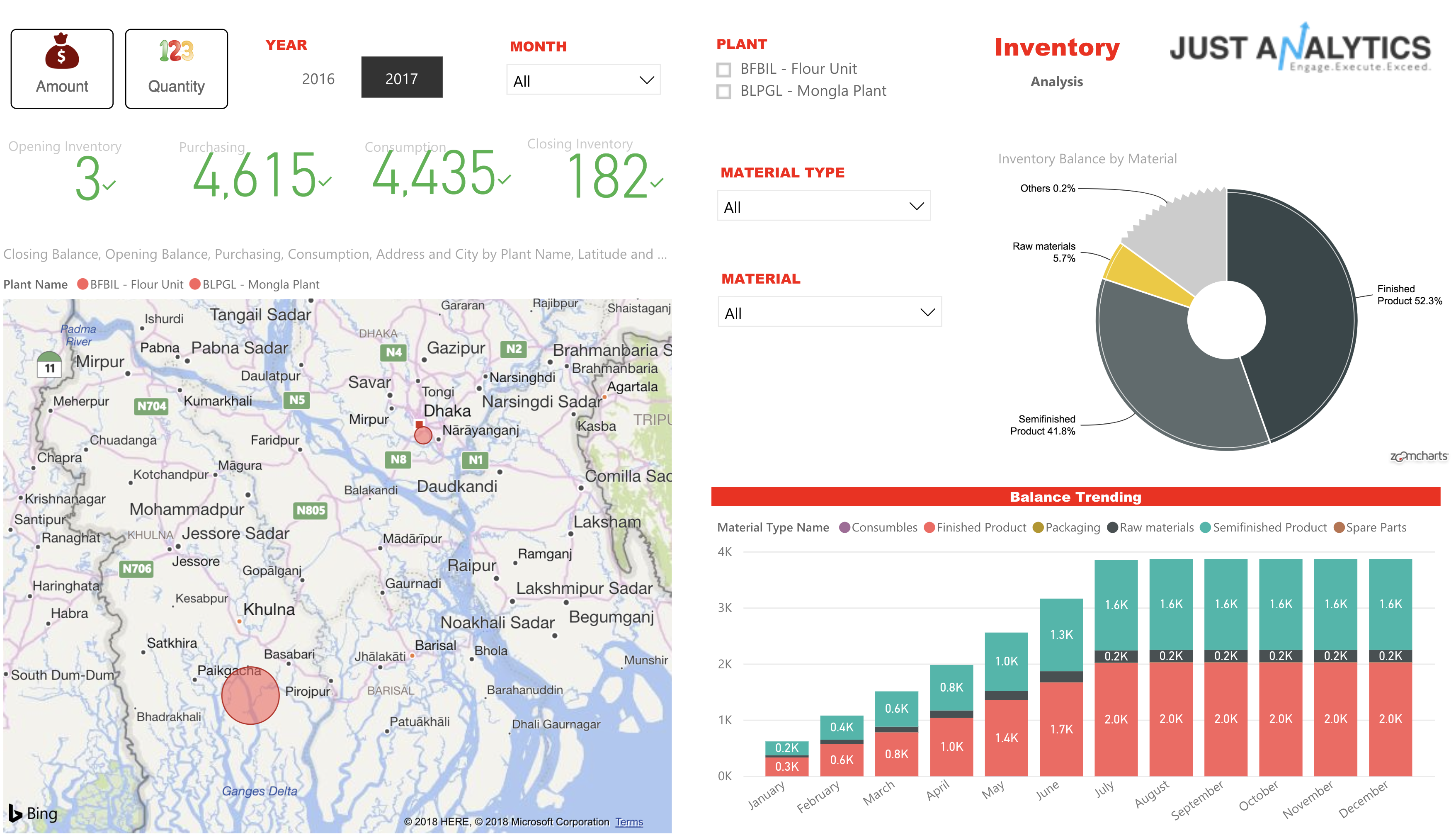

There are several ways for a company to identify slow-moving inventory but all of them rely on data. To benefit from any of these methods you need to have accurate, timely and detailed information on hand as well as the right tools for analysis. Using these techniques, we have developed a solution for one of our customers in retail, allowing them to track and control their inventory providing them with the tools to understand and improve every part of their business.

Inventory analysis can provide you the insights to speed up and improve decision making, identifying opportunities to reduce costs and improve sales. For further details on our solution, check out this link.